Bill of Material

The Different BOMs

When someone refers to the Bill of Material, there are a handful (or more!) of BOMs they could be referring to. It is always important to clarify what one they are implying. There are Engineering BOMs (EBOM), Manufacturing BOM (MBOM), Bill of Process (BOP), Procurement BOM (PBOM), Production BOM (also PBOM), and more depending on your business's lingo. Each one should contain the same info, right??

While the answer is generally "yes!", it is important to know that each BOM could have it's own "view" of the data. For example, the Procurement BOM may not include things like collectors or phantoms, whereas the EBOM will. Additionally there are different effectivities. What is shown in the EBOM on any given day may not actually match exactly what the Production BOM shows, due to part inventory, breakpoints, alternates, and more. As long as each of these differences are properly tracked (i.e. not in Excel stored on Joe Shmoe's computer), usually this doesn't cause a problem. However, what DOES cause problems is when two employees are talking about discrepancies in BOMs, and they are using different BOM views and effectivity.

With this information, it is important to know what for all intents and purposes of the True North PLM training center, we will almost always be talking about the BOMs that live in PLM which rarely have actual production effectivity dates. Again, this depends on your company's business processes.

EBOM vs MBOM vs BOP

The common BOMs present in PLM are the Engineering BOM, Manufacturing BOM, and the Bill of Process. Each contains the same information, but rearranged. The EBOM may be organized by system, by function, or by some other identifier. The MBOM will then rearrange that content into manufacturing assemblies. The Bill of Process takes it one step further and assigns Resources such as stations, operators, and tools to further define how the manufactured assemblies are ordered.

Each of these BOMs are extremely important, and all work together to create a successful product. If one of these are out of sync, you are at risk of having manufacturing problems.

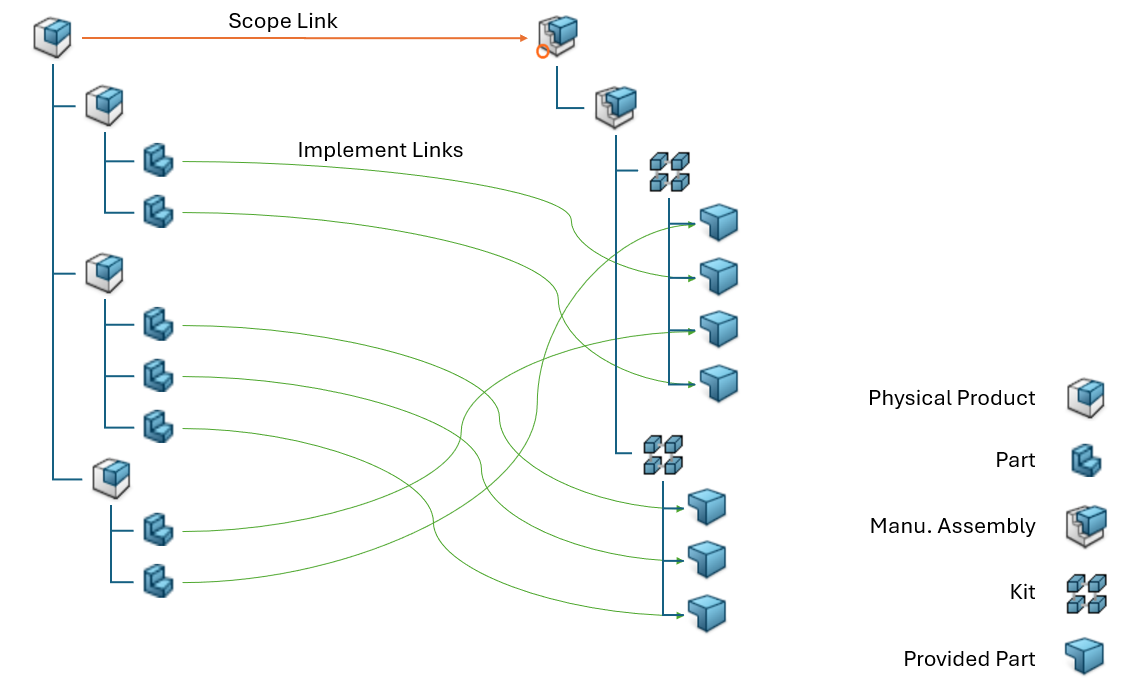

With this knowledge, it is important to understand HOW this information is linked in 3DExperience, which will help you understand how to PRESERVE this information when making changes to your content.

Links Between BOMs in PLM

Every Manufacturable/Procurable instance in the EBOM will result in a connection in the MBOM. The exception to this is "layered" end items, meaning there is an upper level end item such as an assembly, and one of the fasteners is marked end item True for a different instance, but not for the one under the assembly.

Every change in the EBOM will results in a broken link in the MBOM to be resolved.

There are "smart" ways to change the EBOM that will help the downstream users. For example, rather than cutting and pasting content into the EBOM from a study file, it is far preferable to use the Replace mechanism, as this maintains the instance information that the implement link is relying on.

When changing phantoms/collectors, by utilizing revisionsing, duplicate, and save as new, the DELMIA links are better preserved than if a brand new engineering collector is added in. There are other important things to keep in mind such as engineering collector structure. For more information, reach out to True North PLM for additional business consulting.